Metal Badge Process Introduction

Date: 2025-05-04 Categories: INDUSTRY NEWS Hits: 422

Metal Badge Process Introduction

In this era of pursuing individuality and quality, metal badges have become the first choice for people to express emotions and show their identity with their unique charm and exquisite craftsmanship. Today, let us walk into the world of metal badges and explore those amazing craftsmanship details.

Metal badges, as the name suggests, are badges made of metal as the main material. They are usually made of copper, iron, zinc alloy or gold and silver and other metal materials, and are carefully crafted through stamping, die-casting, biting and other processes. These badges not only have simple and smooth lines and well-proportioned patterns, but also appear colorful and highly ornamental due to the use of surface color processes such as baking paint, enamel, and printing.

1. Stamping process

Stamping is the most common process for making metal badges. It uses a die to stamp metal materials to obtain the desired badge shape. Copper badges are the best in stamping because copper is soft and easy to stamp out clear lines and patterns. Iron badges and aluminum badges are also commonly used materials in stamping, each with its own unique texture and beauty.

2. Die-casting process

The die-casting process is mainly used to make complex and difficult embossed hollow badges. The die-casting process uses low-melting-point metal materials such as zinc alloy, which are injected into the mold after heating and then cooled to obtain a formed badge. This process can produce exquisite badges with a three-dimensional and layered feel, which is deeply loved by high-end users.

3. Enamel craft

Enamel craft is the oldest and most exquisite type of metal badge production. It uses enamel powder to color red copper (purple copper), and after high-temperature kiln baking, the surface presents a metallic luster and hardness, just like the texture and color of jewelry. Enamel badges have the characteristics of strong color fixation and long preservation time. They are the first choice for the military, state agencies and particularly commemorative badges, commemorative coins and medals.

4. Imitation enamel craft

The imitation enamel craft is similar to the enamel craft, but the coloring material uses resin paint, so it is also called resin enamel or color paste enamel. The color of the imitation enamel badge is brighter than the real enamel, and the price is more affordable, so it is widely used in the fields of high-end badge customization, commemorative coin production and medals of various companies.

5. Baking varnish process

Baking varnish process is another common process in the production of metal badges. It uses acrylic paint to color the badge, and then bakes it to make the color firmly adhere to the metal surface. Baking varnish badges have obvious concave and convex sense, bright colors, clear metal lines, etc., which is an ideal choice for making mid-to-high-end badges, medals and commemorative coins.

6. Printing process

The printing process is mainly used to make metal badges with complex patterns and rich colors. It uses lithography or screen printing technology to print ink on the metal surface to obtain the desired pattern and color. In order to protect the printed ink from being damaged, the badge is usually covered with glue dripping technology to make it brighter and more durable.

7. Biting process

Biting process is a process that uses chemical solution to corrode the raw materials to obtain a concave pattern. Biting badges have the characteristics of delicate lines and exquisite patterns. It is the preferred process for making high-end badges and commemorative medals.

For more products and services, come to us and consult!

Contact us !

👉WhatsApp number: +86 18002642092

👉Email: market@xsbestheart.com

👉Website: xsbestheart.com

Ball Sports Events

Ball Sports Events  Water Sports Events

Water Sports Events  Fighting Events

Fighting Events  Track And Field Events

Track And Field Events  One-stop service for corporate...

One-stop service for corporate...  Personalized Medals: Create a ...

Personalized Medals: Create a ...  Customised Keychains: Perfect ...

Customised Keychains: Perfect ...  Personalized Commemoration: Cu...

Personalized Commemoration: Cu...  Custom brooches, medals, PINs,...

Custom brooches, medals, PINs,...  Customized Fridge Magnets

Customized Fridge Magnets  XS-YXC10 Steel Cannon Wireless...

XS-YXC10 Steel Cannon Wireless...  XS-YXC9 Creative Wireless Blue...

XS-YXC9 Creative Wireless Blue...  XS-YXC8 Square Magnetic Blueto...

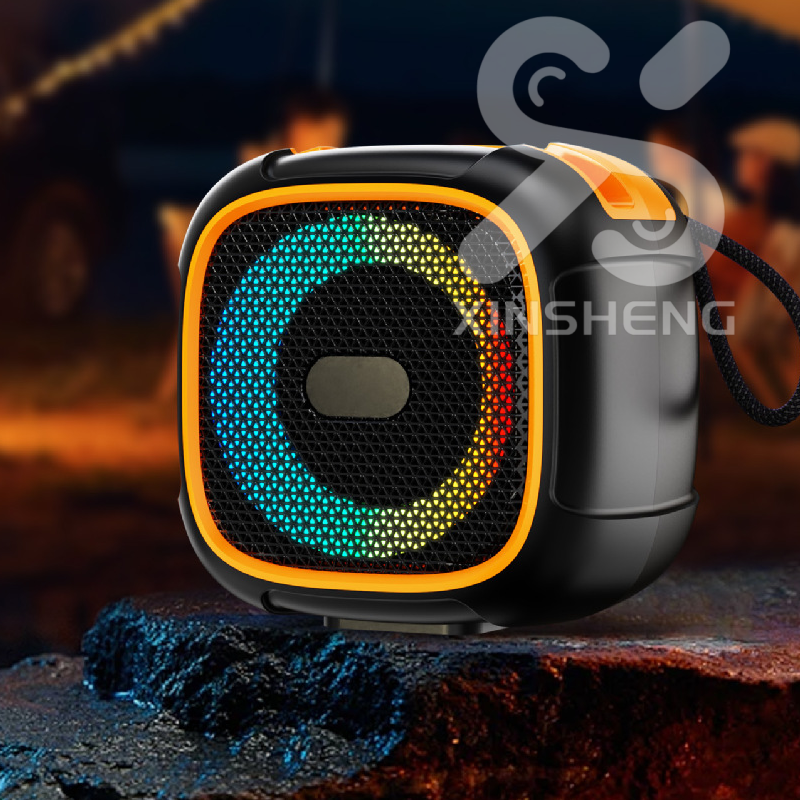

XS-YXC8 Square Magnetic Blueto...  XS-YXC7 Lighting Bluetooth Ste...

XS-YXC7 Lighting Bluetooth Ste...  XS-YXC6 Small Steel Gun Wirele...

XS-YXC6 Small Steel Gun Wirele...  XS-CWA20 Pet Automatic Water D...

XS-CWA20 Pet Automatic Water D...  XS-CWA19 Pet Automatic Feeder

XS-CWA19 Pet Automatic Feeder  XS-CWA18 Gourmet Paradise Soun...

XS-CWA18 Gourmet Paradise Soun...  XS-CWA17 Pet Yellow Duck Hair ...

XS-CWA17 Pet Yellow Duck Hair ...  XS-CWA16 Pet Food Storage Buck...

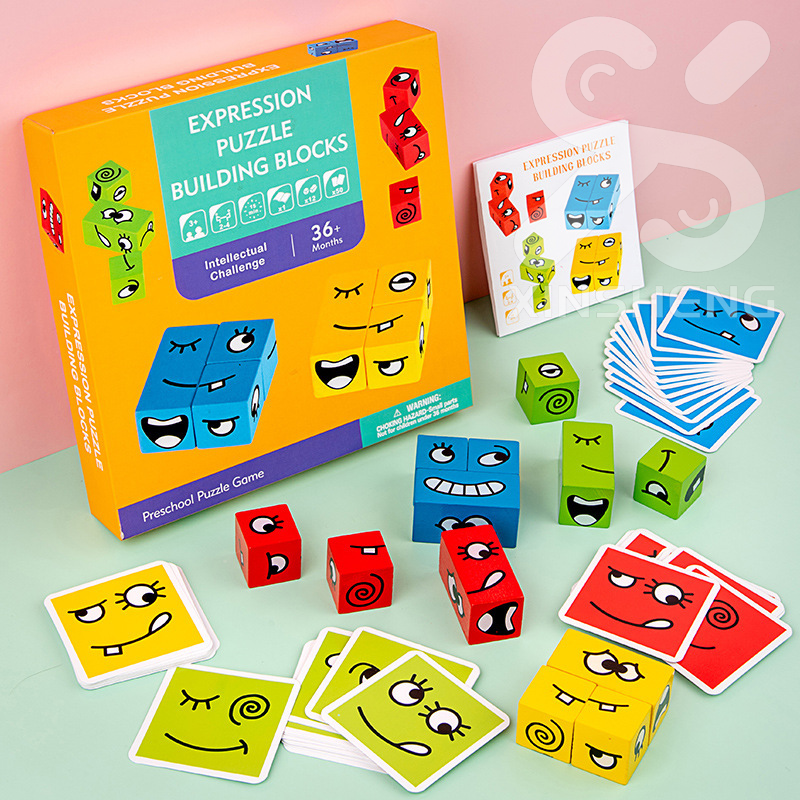

XS-CWA16 Pet Food Storage Buck...  XS-ETA12 Magic Cube Gift Set

XS-ETA12 Magic Cube Gift Set  XS-ETA11 Wooden Magnetic Small...

XS-ETA11 Wooden Magnetic Small...  XS-ETA10 Reaction Contest Gift...

XS-ETA10 Reaction Contest Gift...  XS-ETA9 Wooden Shape Stacking ...

XS-ETA9 Wooden Shape Stacking ...  XS-ETA8 Wooden Magnetic Train ...

XS-ETA8 Wooden Magnetic Train ...